„Make your calculations backed up and give yourself a good night.

It is now the time for FEA!”

FINITE ELEMENT ANALYSIS

FEA

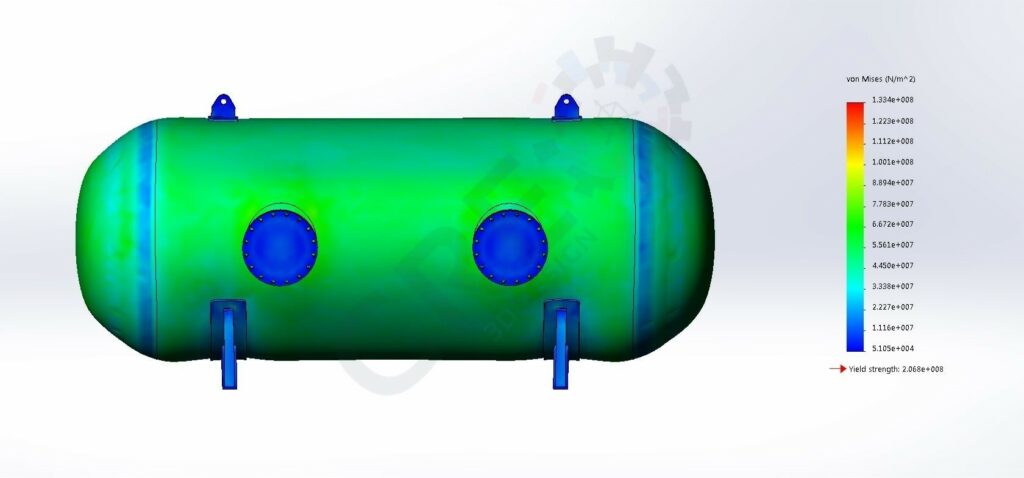

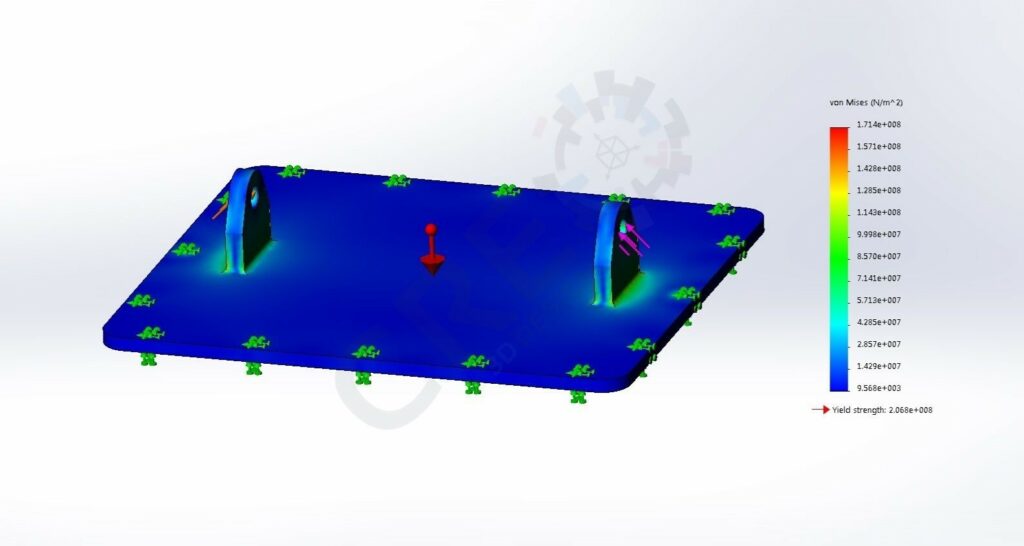

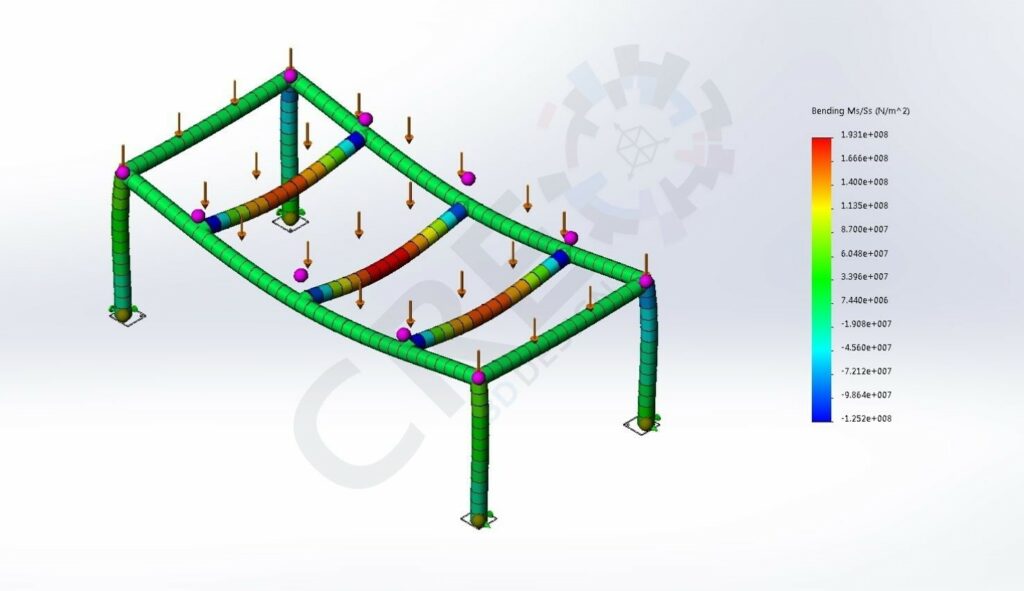

FEA is an abbreviation of Finite Element Analysis which is a method of numerical analysis widely used in engineering environmental and 3D design. In mechanical engineering, FEA is used for solving structural, vibration and thermal problems. We use FEA during the product development process to analyse the design in-progress. Traditional product development needs prototypes to support a design in process. By utilizing the FEA, product design process does not require physical prototype to be a part of the iterative design loop. To take full advantage of this powerful tool, a 3D model is discretized into a mesh of finite tetrahedral elements and nodes. Then, load is applied to the virtual model and results such as stress, strain and displacement can be obtained. Strain and stress are calculated based on the nodal displacement results. By conducting thermal analysis, we can find temperatures, temperature gradients and heat flow. Using motion simulation, we can obtain forces coming from mechanism and then apply them in FEA study as the load. When the FEA process is finished, we can validate our manual calculations, check if model fails by using the appropriate failure criterion, apply a factor of safety or even optimize our product to specific factors, such as minimum weight. Because our design can be very complex, we can conduct many different analyses, for example:

- STATIC

- THERMAL

- FREQUENCY

- BUCKLING

- FATIGUE

- DROP TEST

- LIFTING

- PRESSURE VESSEL DESIGN